Gradient Cotton Yarn/Thread Dyeing Tutorial – Painted Ball Method

Hi Everyone!

Now that I have given a basic breakdown of my past experiments with dyeing cotton yarn/thread into gradient colorways let’s move onto what everyone wants to see a full tutorial!

Today I am going to breakdown my most recent and favorite method of dyeing cotton yarn via the Painted Ball Method, wish I had a better name for it lol!

As noted in my previous post here this is a very time, space and water saving method – well in my eyes at least – and creates some lovely results!

Supplies

1. ProcionMx Fiber reactive dye – see my previous posts about which dyes to buy or not. You can do this with just one color to create a single color Ombre effect or use multiple colors for a gradient effect.

2. 100% Cotton yarn or thread, you can also use any other cellulose fiber or mix of cellulose fibers such as a cotton linen mix, but anything acrylic or wool will not work.

3. Soda Ash or Washing Soda or Sodium Carbonate this is the setting agent for the dye

4. Synthrapol soap or dawn dish soap

5. Urea – Optional, this is an agent that helps dissolve dyes when mixing and keeps moisture present in the batching process

6. Rubber gloves, face mask & art smock or coveralls

7. Measuring cups & spoons

8. Mixing containers, can be plastic cups, containers or squeeze bottles whichever you have

9. 1 liter plastic bucket or container for pre-washing, soda ash soak and rinsing if you don’t want to use your sink

10. Plastic drop cloth or newspapers for workspace covering

11. Digital kitchen scale – this is optional but I use it to weigh my yarn to make the ingredient calculations, but if you know the weight of you yarn based on the label that can be used instead. I don’t use a scale to measure my dye and ingredients, just measuring cups and spoons, this is less accurate but I’m not a professional.

12. Ziploc or seal able bag & saran wrap – saran wrap is optional but I find it keeps the dye run off tidy in the bag.

13. Paper towels and cloth rags

14. Tin roasting pan to work in

15. Yarn swift and niddy noddy – these are optional but a big time saver see my supplies post

Step 1.

Calculations

First I need to do some simple calculations to ensure that I get the colors I want based mostly on the weight of my yarn.

Depth of Shade/DOS

Depth of Shade or DOS refers to how dark/saturated a color you wish to produce, for example a 5% DOS will produce a fairly dark/saturated version of the color, whereas a 1% DOS would be more pastel looking and a 3% DOS would be somewhere in the middle. Calculating DOS will then determine how much dye powder you will need to measure out. I usually work with 5% DOS to get a very saturated color that can then lighten as it penetrates the ball, but this up to taste.

Calculation;

Weight of Fiber/WOF x DOS = how many grams of dye powder to use

Ex. WOF = 100gms x DOS= 5% = 5gms dye powder or 100gms x .05 = 5gms dye powder

Dyestock Strength

Now that I have determined the DOS I want to use I will calculate my dyestock strength, this means figuring out how much mixing water to add to the dye powder to get the DOS I desire.

Calculation;

Gms of dye x ml of mixing water

Ex. Gms of dye = 5gms x mixing water = 100ml = 5% DOS dyestock

Ex 2. Gms of dye = 5gms x mixing water = 150ml = 3% DOS dyestock

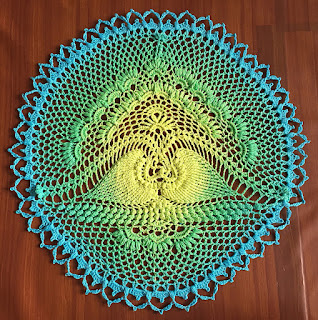

Optional Dyestock Use Estimation

Next up in my calculations I will estimate how much yarn I want to be dyed with each color, so for example if I was doing 4 colors on a 100gm ball I will estimate that I want to dye about 10gms of the ball the first color, 20gms of the ball in 2nd color, 25gms of the ball in 3rd color and 45gms in the 4th color. I do this because the designs I work with are circular doilies that work out from the center and I want to create a full color change across the design. If I dyed each color the same amounts it would end up leaving not much color progression see below.

After I figure out these estimates it’s just a matter of converting gms to ml to determine how many ml of dyestock in that color that I will measure out to use. I try to mix up as small amount of dyestock as I can to cut down on waste, and often do more than one ball at a time so I can use up as much dye as possible.

So for the above project I would need color 1 = 10ml, 2 = 20ml, 3 = 25ml, 4 = 45ml. This is a very small amount of dyestock to mix up and would require a precise scale to measure out such a small amount of dye powder, which is why I recommend mixing up a solution in at least 100mls of water and subtracting the exact amount you need instead. Or you can just mix up 100mls of your dyestock solution and estimate how much you are going to use as you paint it on the ball.

Soda Ash Solution

Typically I will mix up a soda ash solution in a big 1 litre

empty iced tea jug and keep it set aside for future projects, once mixed soda

ash solution does not go bad. For soda ash I follow the dye manufactures recommendation

of 100gms soda ash mixed with 1 litre/1000ml/4cups of warm water between

95-110F or 35-45C, this makes a soda ash solution at 10% strength. Give the bottle a good shake until powder is dissolved and

set aside after labeling to cool to room temperature.

Urea water

Using urea in your dye mixing water is optional, it can make some dyes like fuchsia and other reds easier to dissolve and will keep your yarn wet during the batching/setting time resulting in more vibrant colors. Otherwise using plain old tap water to mix your dyes will suffice.

As per dye manufactures recommendation add 1 tablespoon of urea to 100ml warm water, or mix up 10 tablespoons in a 1 litre bottle if you are doing a big project. Since urea has to dissolve in warm water between 95-110F or 35-45C its best to mix the urea water separately like the soda ash and set it aside to cool down to room temperature so that it doesn’t affect the dyes when mixing.

Dyes should be mixed with water in temperatures between 75-95F or 25-35C to ensure that the heat does not cause the dye to react with the mixing water rather than the fiber, this can result in paler colors. The exception is turquoise which reacts slower and at temps around 110F or 45C, but will do fine with lower temperatures above.

Step 2.

Prep and setup

Setup your workspace

First prepare and setup your workspace, I work in my kitchen so I make sure to clear off the counters and wash up all my regular dishes so that there’s nothing on the counters or in the sink when working with dyes and chemicals. Cover your surfaces with your plastic drop cloth or newspapers, I cover up my kitchen island counter where I do the majority of my work but not the floors, I have laminate floors and will just do a quick Swiffer mop after I’m done to clear up any drips or spills, to each their own.

Wash and soak yarn

To prep your yarn/thread will be dependent on if you want to wind your yarn into a ball off a skein or not, having a yarn swift to make a skein and wind off into a ball as you dye is really helpful but you could also make your skein by wrapping your yarn around the legs of two chairs. If that’s too labor intensive or you don’t want soda ash or dye possibly staining your furniture you can skip making a skein and proceed to scour and soak your yarn either in the ball it came in or wrap into a ball.

Once you have made your skein or ball of yarn soak and scour it in hot water and soap for about 20 minutes, wring out and move into the 1 liter plastic bucket. Fill the bucket up with pre-made soda ash solution until it covers your yarn. If your yarn is in a ball be sure to give the ball a good squeeze to get as much soda ash solution into the ball as possible. Let this soak for 20mins to an hour, during which time you can mix up your dyes.

Mix dyestocks

Dyestock mixtures, while wearing gloves, face mask and some sort of covering on your clothes, set aside your measuring cups, urea water or mixing water, mixing cups, measuring spoons and mixing utensils into your tin roasting pan to catch your spills leaving less to clean up on your drop cloth.

|

| Here's my kitchen island all covered and set up to mix up my dyestocks, I kept them in the mason jars until I measure out the amount I want to use for each ball into a squeeze bottle. |

When measuring out dye powder with your measuring spoons be sure that the spoons are clean of any other dye but also that they are completely dry to keep moisture out of your dye powder jars. Once in your mixing container, add a small amount of urea water at first and mix the dye into a paste before adding the rest of your water and mixing until all powder is dissolved. Set aside your mixed dyestocks in the containers you will be using, for me squeeze bottles.

In this example I am doing a 70gm ball of white thread with 3 colors as per my calculations above, I have mixed my 5gms of dye powder with 100mls of urea water in the following colors, Fuchsia, Peach and Emerald. I will use 10 ml of fuchsia, 25mls of peach and 35ml of emerald.

Step 3.

Dyeing/Pouring/Painting

Now that all the dye is mixed up I will remove my mask and change my gloves or wash and dry them to ensure no stray dye is on them for when I handle the yarn.

Remove your yarn from the soda ash water and wring out until slightly damp, remember to wear gloves doing this because the soda ash can act as an irritant on your skin. You can pour left over soda ash solution back into your bottle, it may lose some of its strength but no use in wasting it.

Place your skein onto your yarn swift or over 2 chair legs, or if using straight from the ball place in the now empty bucket to keep the ball in a clean place as you wind it in another ball while dying. Set out your dyestock colors and your clean tin roasting pan and a plastic bowl or container in the tin pan to catch run off dye.

|

| 3 colors used for this ball, fuchsia, peach and emerald |

Begin winding your yarn into a tight ball for a bit, then begin to wind the ball more loosely say around 2-3 fingers for a while based on your estimates of how much you want to dye in color 1.

| ||

| Wrapping the ball tight at the beginning will give a very pale penetration of the color 1 with a bit of white at the beginning. |

|

| Wrap the ball loose around a few fingers, this may result in a bit of tangling at then end but nothing too dramatic. |

Over the plastic container or bowl in your tin roasting pan, start pouring your dye for color 1 over the ball until it is covered. Squeeze the ball and wring out this dye into the bowl, then roll the ball around in it and soak it back up. Do this a few times but be sure to soak up the remaining dyestock in the bowl or pour down the sink once you are done, it should not go back into the bottle with your left over dyestock as it has now come into contact with soda ash and it will spoil the remaining dyestock you have left over in the bottle.

|

| Soaking up left over color in the bowl |

| ||||

| Wrap tightly until you are seeing more white than color before wrapping loosely again |

|

| Ready for color 2 peach |

At this point I will wash and dry my gloves to get as much of color 1 off my gloves before moving onto color 2, this should be done between each color.

|

| Tight wrapping again |

|

| Your next emerald |

|

| And the final color Emerald |

Once all dye colors have been applied wrap the ball up in a piece of saran wrap and place in to a ziplock or sealable plastic bag. Place this bag somewhere relatively warm to batch/set for the next 12-24 hours.

|

| Saran wrap keeps excess dye from running out into the bag |

|

| All bagged up and ready for batching |

Now all that’s left for the day is to clean up your workspace, so easy!

Step 4.

Rinsing & Drying

After batching/setting overnight take the ball out of the

bag, I usually rinse and dry these bags to reuse to cut down on waste but throw

away the saran wrap.

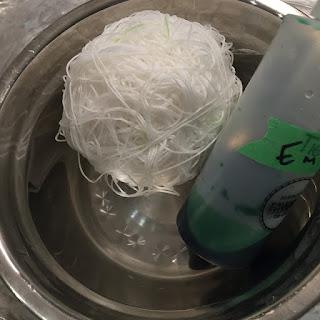

Give the ball a quick rinse in cool water in the sink, squeeze out and put in plastic bucket to contain the ball as you unwind it into a skein.

|

| Quick Rinse in cool water before winding into a skein |

At this point unwinding the ball into a skein is essential to be able to properly rinse out the soda ash, excess dye and dry out, you will not be able to allow the ball to dry in ball form and then use, never done it but I can’t imagine that working out well.

However you need to do it, either with a yarn swift or niddy noddy or around some chair legs, be sure to wear a long sleeved shirt and rubber gloves to catch any soda ash or water that come off as you unwind the ball so it doesn’t get on your skin and cause irritation or staining. Tie up your skein to keep from tangling and take back to the sink for rinsing.

|

| Ball in bucket to keep it clean while winding into a skein, I like putting paper towels in there to soak up extra water |

|

| Tie onto the niddy noddy, bad me not taking my own advice on gloves and long sleeve shirts, I did put them on eventually I swear! |

|

| A little tangle that I will fix up during this time, excuse my toe lol! |

|

| But it is just so fun to see the color transitions work out as I wind them onto the niddy noddy |

|

| Ain't she a beauty? Future Indunn doily |

|

| All tied up and ready for rinsing, note colors will be darker before the rinse out and dry |

Run the skein under cool/cold water to wash out the remaining soda ash, rinsing this out ensures that any unfixed dye left in the skein will not set where it spreads when you soak it in hot water causing color bleeding.

|

| Initial cold rinse under the tap to get soda ash out. |

Fill up your sink, wash basin or bucket with the hottest water your tap will provide, add a small drop or two of synthrapol soap or regular dish soap, then put the skein in to soak for an hour or until the water cools. If after the hot soap soak you still find color running out of your skein do another hot soap soak until it runs clear or clearer.

|

| Only need a small amount of soap in hot soak. |

|

| Splish Splash I'm having a bath! |

Wring the skein out and hang up or lay out somewhere to dry, usually takes 24-48 hours to be dry before you can wind back into a ball for use.

|

| And there they all are hanging up to dry over the bathtub on coat hangers, will be 24 hours min to dry |

Below are the pre-dry results of my biggest dye day yet, I dyed 8 balls of thread in about 8 hours, if I had mixed up my dyestock the night before it might have taken less time. Or better yet if I had more measuring spoons and squeeze bottles there would have been less washing between colors.

Winding and pouring on dye for each ball really only takes about 20-30 minutes depending on how big the ball and how many colors used. Then I just left them all to sleep in their little ziplock cocoons before they emerged the next day on my niddy noddy for winding & rinsing day.

|

| Future Teagan doily, in aquamarine, turquoise, fuchsia and lilac |

|

| Future Camilla doily in peach, lilac and turquoise |

|

| Future Fairie doily in golden yellow, lilac and warm black |

|

| Future Amal doily in bright green, emerald and teal |

|

| Future Irida doily in lilac and teal |

|

| Future Birgitta doily in peach, golden yellow, aquamarine and teal |

|

| Future Emma doily in golden yellow, fuchsia, aquamarine and teal |

And that’s it! That is my newest and favorite method of

dyeing gradients for cotton thread, thanks for reading, I hope you find it useful in your dye adventure!